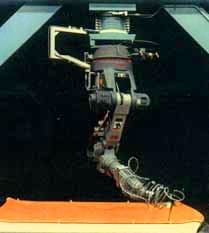

Robotic Waterjet Cutting of Insulation

Bostik are a leading manufacturer and supplier to industries globally and rely on our robotic technology to meet a requirement of over 180,000 firewall insulators each year. The insulators are made and supplied under the “Just in Time” practice, requiring extreme flexibility to cope with the varying mixture of design types.

At their highly innovative manufacturing plant in Thomastown Victoria, Bostik use 2 cells supplied by Robotic Automation for waterjet cutting of firewall insulators. Each cell contains 2 Motoman robots operating in conjunction with a 6 station-rotating carousel, running 24 hours a day, 6 days a week.

Continuous Operation

Laminated insulator castings are manually loaded into 2 location nests outside each soundproof cell. While the robots are cutting 2 previously loaded blanks inside each cell, completed insulators are unloaded from the remaining 2 stations. This carousel arrangement ensures the robots are operating continuously, giving maximum output.

With the first cell containing 2 Motoman robots, carousel and safety enclosure installed over 3 years ago, Bostik had no hesitation in choosing Motoman robots from Robotic Automation when they needed another cell to meet increased demand. In both investments, engineers from Robotic Automation worked closely with Bostik to design and supply a turnkey robotic system that would meet their current needs and include room for expansion.

Flexibility

Flexibility is the key to the success of the robots. Continual variations and improvements by Bostik necessitates change; the ease and speed of reprogramming the Motoman robots enables enhancements to parts “on the run” and at far less cost than conventional tooling changes.

Very fine jets of water at high speed are used to actually cut the insulators, with the robot head programmed to move along a required path to an accuracy of less than 0.1 mm. The result is insulating cut to meet exacting specifications; consistently, accurately and repeatedly.