Mobile Robots

Robotic Automation™ understands the capabilities of Mobile Robots and the most efficient way they can be utilised to benefit your business.

Warehouses and manufacturers are consistently looking to increase flexibility and improve production cycles, whilst reducing rates in handling, storage and retrieval services. As there are different pallet types and storage requirements for different products, AGV systems need to be adaptable, changeable and easy to work with ‘on the fly’.

Warehouses and manufacturers are consistently looking to increase flexibility and improve production cycles, whilst reducing rates in handling, storage and retrieval services. As there are different pallet types and storage requirements for different products, AGV systems need to be adaptable, changeable and easy to work with ‘on the fly’.

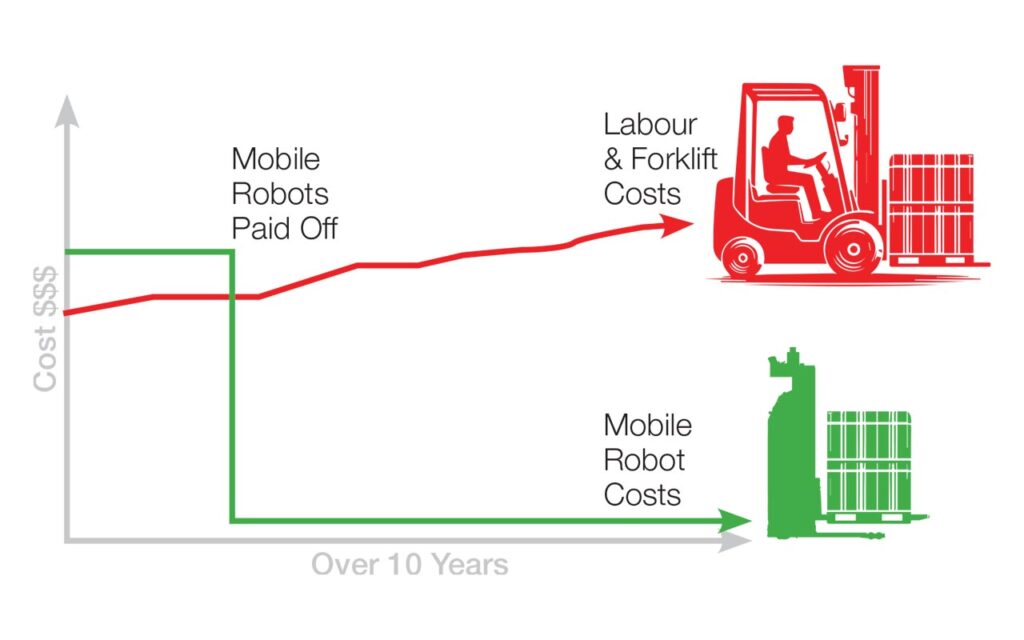

Fast ROI

With ever increasing labour shortages and costs, why would you employ staff to move material that can move itself?

There are many use case scenarios where repetitive movement of products and material can easily and more efficiently be completed by Mobile Robots.

This chart demonstrates how quickly running costs drop after the pay-off period is reached.

There are many use case scenarios where repetitive movement of products and material can easily and more efficiently be completed by Mobile Robots.

This chart demonstrates how quickly running costs drop after the pay-off period is reached.

What’s the Difference?

AGV

Automated Guided Vehicle

AGVs follow pre-programmed paths only.

The analogy of a train line is often used when referring to AGV operations. They are assigned specific paths to follow and will not deviate from these paths.

If the AGV’s path is blocked, it will stop and notify the system of the anomaly until the path is cleared or another path is added using the smart, window-based software.

The analogy of a train line is often used when referring to AGV operations. They are assigned specific paths to follow and will not deviate from these paths.

If the AGV’s path is blocked, it will stop and notify the system of the anomaly until the path is cleared or another path is added using the smart, window-based software.

AMR

Autonomous Mobile Robot

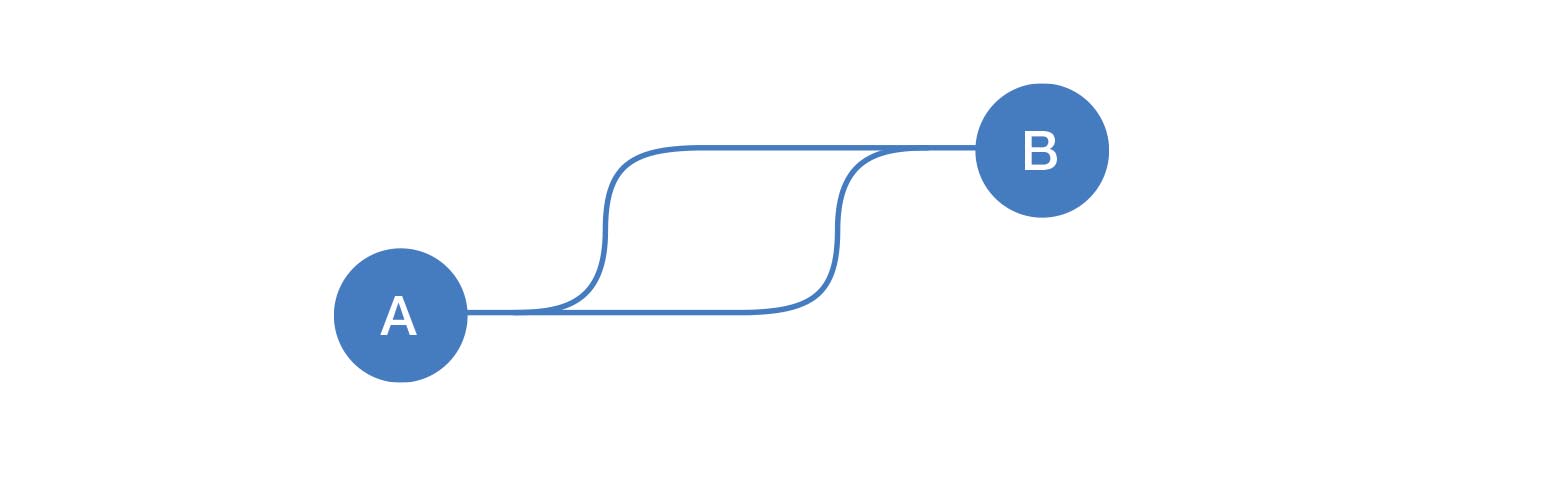

AMRs self-manage paths within a pre-programmed zone.

The AMR system uses SLAM technology to find its own way between pickup and drop-off locations.

If the AMR’s path is blocked it will try to find a way around the obstacle to meet its objective.

The AMR system uses SLAM technology to find its own way between pickup and drop-off locations.

If the AMR’s path is blocked it will try to find a way around the obstacle to meet its objective.

AGV Range

We found the best in AGV solutions, so you don’t have to.

Our exclusive partnership with MAXAGV means that you can take advantage of the benefit of technological leadership, single-source equipment supplies and integration, and consistency in high level aftermarket support.

Our exclusive partnership with MAXAGV means that you can take advantage of the benefit of technological leadership, single-source equipment supplies and integration, and consistency in high level aftermarket support.

Forklift AGV Range

Carrier AGVs

Carrier AGVs can operate with conveyors, trolleys and low-rack stations by traveling under the load and lifting vertically or alternatively by receiving and transferring the load horizontally from conveyor systems.

With twin conveyors, the Carrier can handle multiple loads and can unload simultaneously or at multiple destinations.

With twin conveyors, the Carrier can handle multiple loads and can unload simultaneously or at multiple destinations.

Carrier AGV Range

CX SERIES

CXH

- Hospital Trolley Carrier

CX SERIES

CX10

- Twin Tote Carrier

CX SERIES

CX15

- Industrial Pallet Carrier

CX SERIES

CX30

- Multi-load Carrier

CX SERIES

CX100

- Maxi Carrier

MAXAGV Advanced Control System

The MAXAGV Control System is Windows based and a clear leader in its field. The system optimises logistics, handling everything from transport and warehousing, load tracking, buffering and order swapping to optimal dynamic route selection, location selection, charge control, priorities and dead lock prevention – all shown in real time 3D visualisation.

The control system runs on a Microsoft Windows environment and features a user-friendly interface that is easy to learn, configure and use, allowing customers to make changes ‘on the fly’ in real time application.

The MAXAGV Control System is operational via PC, tablet and smart phone.

The control system runs on a Microsoft Windows environment and features a user-friendly interface that is easy to learn, configure and use, allowing customers to make changes ‘on the fly’ in real time application.

The MAXAGV Control System is operational via PC, tablet and smart phone.

AMRs

Robotize is a leading manufacturer of collaborative mobile robot solutions based in Denmark.

They specialize in the design of AMRs (Autonomous Mobile Robots) specifically for material transport within factories and warehouses.

They specialize in the design of AMRs (Autonomous Mobile Robots) specifically for material transport within factories and warehouses.

Modular Delivery Robot

The latest RA-MR autonomous mobile robot can be used indoors and outdoors for intralogistics and perimeter security patrol.

- Intralogistics Transportation

- Consumables Deliveries

- Meal Deliveries

- Waste Transportation

- Perimeter Security Patrol

Comprehensive support throughout the life of your equipment.

Robotic Automation™ Service Agreements are a cost-effective method of providing maintenance and technical support to keep your operations running. Our service agreement customers receive:

- Scheduled Annual Services

- 24 Hour Breakdown Service

- Discounts on Labour and Spares

- Customer Training and Support

- Telephone Support

- Planned Upgrade Management

- Customer Loyalty Benefits

- Consultancy Services

Case Study

Explore real-world success stories highlighting how Robotic Automation™ delivers innovative solutions and tangible results across industries.

Our Valued Customers

Testimonials

Read first hand accounts from clients who have experienced transformative results with our robotic automation solutions.

“One of the best executed projects I have been involved in whilst working for Downer”

Andrew Elkin

Head of Technology & Innovation Facilities & Asset Services, Downer Group

“I am extremely satisfied with the efficiency and reliability of our automated warehousing solution. The after sales service and technical support provided by the RA team has been exceptional.”

Domenic Tacca

Managing Director, Tacca Industries

‘After many months of careful consideration, looking at robotic solutions, we felt that Robotic Automation provided the best solution for increasing the efficiency and productivity of our steel manufacturing system. Their experienced team took time to review our manufacturing processes and identify opportunities to increase our production output, creating an automation solution which will provide flexibility for our business to grow and expand well into the future.’

Stramit

‘Robotic Automation provides service and support to our business which is second to none. Their experienced technicians have a detailed understand our business requirements and provide solutions which are adaptable to the ever-changing needs of our business’.

Matthew Kelm

Opal Group

Have questions? We're here to help.