Pallet Wrapping and Strapping

Robotic Automation™ provides a comprehensive range of automated pallet wrapping and pallet strapping solutions, engineered to integrate seamlessly with your existing end‑of‑line packaging processes. Our systems are designed to enhance throughput, reduce manual handling, and ensure every pallet leaves your facility wrapped to the highest standard of security and presentation.

Automated stretch wrapping delivers consistent load containment, stability, and protection for palletised products. By introducing automation into your wrapping process, you significantly reduce consumable usage, improve presentation consistency, and minimise the risk of product damage as goods move through the distribution chain toward store delivery.

Automated stretch wrapping delivers consistent load containment, stability, and protection for palletised products. By introducing automation into your wrapping process, you significantly reduce consumable usage, improve presentation consistency, and minimise the risk of product damage as goods move through the distribution chain toward store delivery.

Many Benefits

- Greater speed and efficiency. Automated pallet wrappers streamline your end‑of‑line operations, improving throughput and maintaining consistent cycle times—ideal for growing production demands.

- Reliable consistency and repeatability. Each pallet is wrapped with uniform tension and patterning, eliminating human error and ensuring dependable load stability every time.

- Significant cost reductions. Automation cuts labour costs and reduces stretch film consumption through precision control and pre‑stretch technology, maximising every metre of film..

- Automatic film roll change options. Advanced systems allow for uninterrupted production with automated roll changes—boosting productivity across multi‑shift operations.

- Enhanced safety for workers and products. Reduced manual intervention means fewer injuries, less forklift congestion, and improved protection for your goods throughout transport.

- Improved traceability and integration Automated pallet wrappers can incorporate SSCC pallet labelling and integrate seamlessly with warehouse management systems, enabling full traceability and efficient logistics management.

Huge Range

-

Robotic Automation™ offers one of the most extensive ranges of automated and semi‑automated pallet wrappers in Australia including:

- Semi‑automatic vertical stretch wrappers.

- Fully automatic, high‑speed pallet wrapping systems

- Horizontal and vertical configurations.

- Turntable stretch wrappers

- Rotating arm conveyor systems

- Orbital (ring) horizontal wrappers

From compact stand‑alone units to large‑scale multi‑line automated pallet wrapping systems, we design, supply, and install solutions tailored to your exact workflow and operational requirements.

Tailored Solutions

-

At Robotic Automation™, we work closely with you to recommend the ideal automated stretch wrapping system based on:

- Your production environment and layout

- Product type, weight, and shape

- Primary and secondary packaging needs (including shelf‑ready packaging)

- Required throughput, capacity, and film performance

- Existing conveyor or end‑of‑line infrastructure

- Budget and future scalability

By understanding your factory and warehouse setup, we identify inefficiencies, uncover potential cost savings, and deliver an automated pallet wrapping solution engineered to improve productivity across your entire supply chain.

Self-Propelled Wrapping Robot

This Robot can stretch wrap and stabilize palletised loads of any size and provides a high level of autonomy and great work flexibility.

It is easy to operate and can be set up to apply the film with perfect pre-stretching and low film consumption. We have also tested this machine with biodegradable film from Great Wrap (https://greatwrap.com.au/) with great success.

It is easy to operate and can be set up to apply the film with perfect pre-stretching and low film consumption. We have also tested this machine with biodegradable film from Great Wrap (https://greatwrap.com.au/) with great success.

Turntable Stretch Wrapping

As the name suggests, these machines operate via a turntable that rotates the product load while stretch film is applied. These machines have the benefit of being portable for use, providing flexibility across the factory floor and represent a lower cost option.

In-Line Turntable Stretch Wrapping

In-line, automatic wrapping stations are ideal for fixed conveyor, end-of-line packaging where high productivity is a requirement.

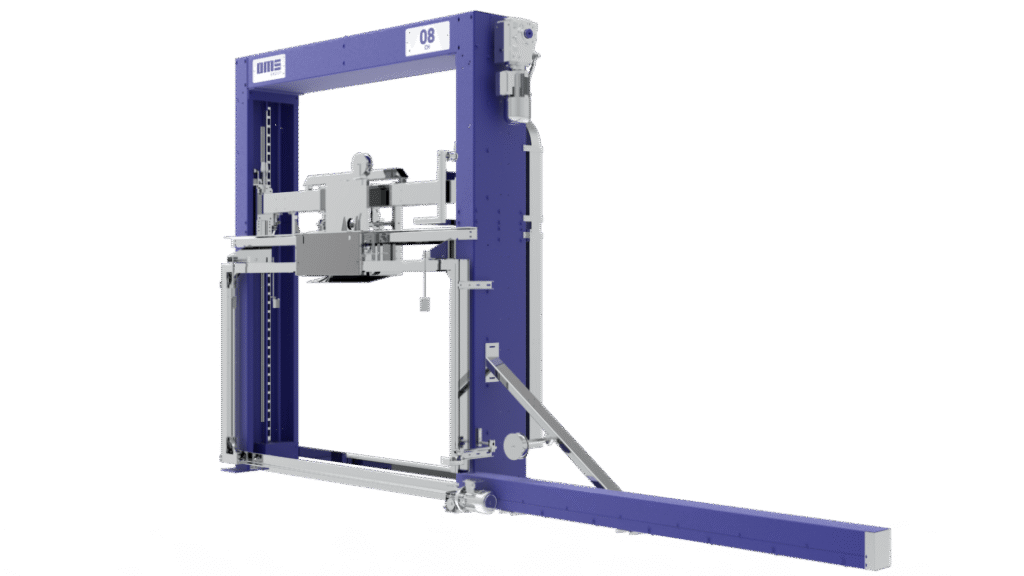

Rotating Arm Stretch Wrapping

This technology enables wrapping of product on a fixed pallet position with a robotic arm rotating around the load, applying stretch film as it rotates. This option minimises risk of load movement.

Induction Ring Stretch Wrapping

The unique Saturno ring wrapper uses magnetic induction to power the inner ring, eliminating electrical connections and wearing parts. This machine is suitable for the high-speed wrapping of palletised loads. The machine is available with of 2 or 4 steel columns in which the rotating ring is housed.

Orbital Horizontal Stretch Wrapping

These machines are designed to wrap the load over and under, which is beneficial for some products that are less uniform in shape.

Automatic Vertical Strapping Machine

These machines have been specifically designed for vertically strapping palletised product.

They can be installed in-line on fixed conveyor with automatic strapping programs customized according to the sizes of the packages and of the logistic requirements.

Comprehensive support throughout the life of your equipment.

Robotic Automation™ Service Agreements are a cost-effective method of providing maintenance and technical support to keep your operations running. Our service agreement customers receive:

- Scheduled Annual Services

- 24 Hour Breakdown Service

- Discounts on Labour and Spares

- Customer Training and Support

- Telephone Support

- Planned Upgrade Management

- Customer Loyalty Benefits

- Consultancy Services

Case Study

Explore real-world success stories highlighting how Robotic Automation™ delivers innovative solutions and tangible results across industries.

Our Valued Customers

Testimonials

Read first hand accounts from clients who have experienced transformative results with our robotic automation solutions.

“One of the best executed projects I have been involved in whilst working for Downer”

Andrew Elkin

Head of Technology & Innovation Facilities & Asset Services, Downer Group

“I am extremely satisfied with the efficiency and reliability of our automated warehousing solution. The after sales service and technical support provided by the RA team has been exceptional.”

Domenic Tacca

Managing Director, Tacca Industries

‘After many months of careful consideration, looking at robotic solutions, we felt that Robotic Automation provided the best solution for increasing the efficiency and productivity of our steel manufacturing system. Their experienced team took time to review our manufacturing processes and identify opportunities to increase our production output, creating an automation solution which will provide flexibility for our business to grow and expand well into the future.’

Stramit

‘Robotic Automation provides service and support to our business which is second to none. Their experienced technicians have a detailed understand our business requirements and provide solutions which are adaptable to the ever-changing needs of our business’.

Matthew Kelm

Opal Group

Have questions? We're here to help.