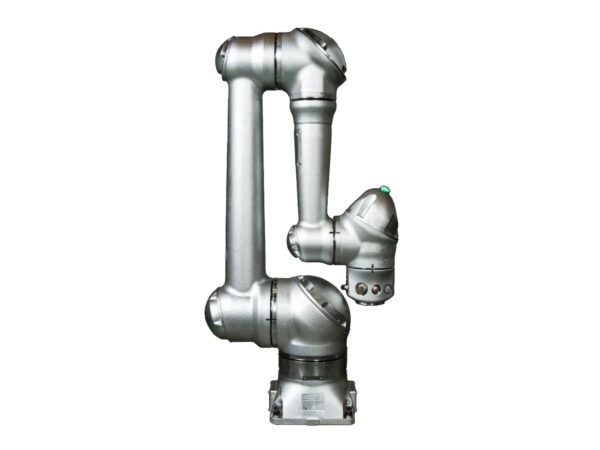

Human Colloborative Series

Highly versatile and portable, HC series Cobots are ideal for a variety of tasks.

- Machine Tending

- Material Handling

- Packaging & Palletising

- Welding

- Light Assembly

Robots continue to be used throughout extensive applications, addressing the growing global challenge of skilled labour shortages in manufacturing.

Today, robots are tasked with a variety of roles beyond simple repetitive tasks. However, small and mid-sized companies face hurdles in robot implementation due to safety requirements necessitating separate working areas.

The Motoman Yaskawa human collaborative robot (HC10) offers an affordable, versatile, and user-friendly solution. These robots cater to customers seeking seamless automation, enabling them to work alongside humans.

Cobots

Cobot Palletising

Pallet Builder Software

The included product database is scalable to meet your business needs, with guided prompts for cell configuration as well as pallet pattern setup and programming. This no-code platform is ideal for small- to medium-sized enterprises with little to no programming experience.

Cobot Welding

Experience increased productivity with high welding seam standards.

Weld Builder Software

Comprehensive support throughout the life of your equipment.

Robotic Automation™ Service Agreements are a cost-effective method of providing maintenance and technical support to keep your operations running. Our service agreement customers receive:

- Scheduled Annual Services

- 24 Hour Breakdown Service

- Discounts on Labour and Spares

- Customer Training and Support

- Telephone Support

- Planned Upgrade Management

- Customer Loyalty Benefits

- Consultancy Services

Case Study

Our Valued Customers

Testimonials

Read first hand accounts from clients who have experienced transformative results with our robotic automation solutions.

Andrew Elkin

Domenic Tacca

Stramit

Matthew Kelm

Have questions? We're here to help.