Efficient Robotic Palletising Solutions

- Handles diverse product types (boxes, bags, bottles, cartons)

- Maintains consistent pallet quality across fluctuating production volumes

- Operates continuously, supporting 24/7 manufacturing environments

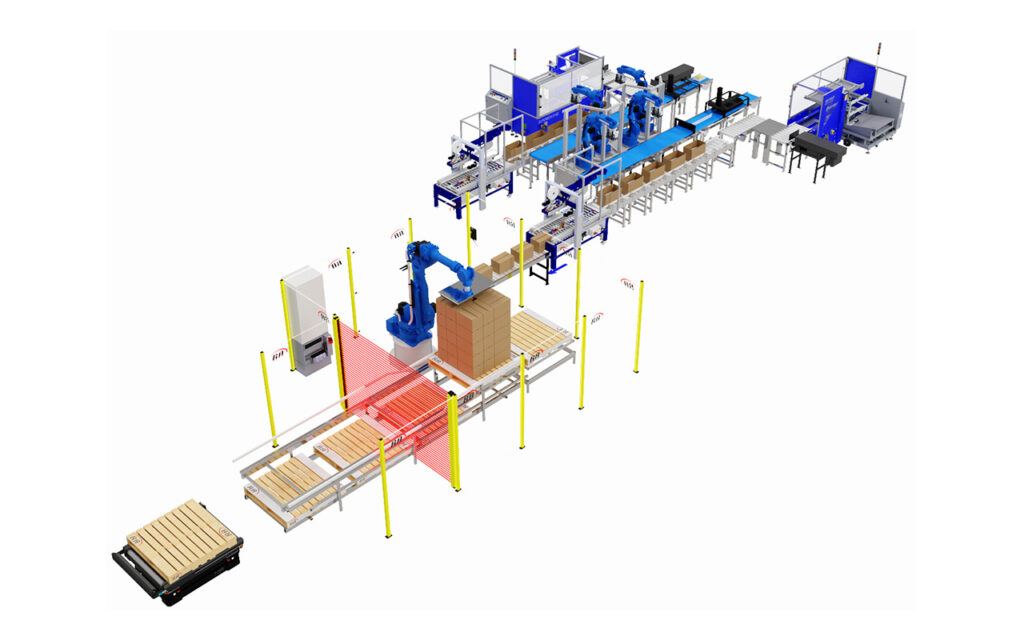

Highly Flexible Cells

- Scalable configurations for both single‑line and multi‑line palletising

- Wide range of gripper options for different product shapes and packaging

- Centralised or end‑of‑line setups to fit existing plant layouts

Seamless Integration

- Seamless integration with stretch wrapping, packing and storage systems

- Compatible with AGVs/AMRs for automated pallet transport and retrieval

- Reduces manual handling risks and operational labour costs

Palletising Solutions

Standard Cells

Contact us to see if you can benefit from one of these solutions and enjoy the lower investment and faster to market benefits they offer.

Custom Cells

Mixed Palletising

Pack and Palletise Combined Cells

Gripper Technology

Cobot Palletising

End-Of-Line Palletising and Logistic Processes offer high application potentials for cobots. 1900mm reach and 20 kg payload make the HC20DTP perfectly suitable for fenceless palletising operations. Due to the IP67 protection class and integrated food grade grease, applications in the pharmaceutical and medical industry are possible.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Comprehensive support throughout the life of your equipment.

Robotic Automation™ Service Agreements are a cost-effective method of providing maintenance and technical support to keep your operations running. Our service agreement customers receive:

- Scheduled Annual Services

- 24 Hour Breakdown Service

- Discounts on Labour and Spares

- Customer Training and Support

- Telephone Support

- Planned Upgrade Management

- Customer Loyalty Benefits

- Consultancy Services

Case Study

Our Valued Customers

Testimonials

Read first hand accounts from clients who have experienced transformative results with our robotic automation solutions.

Andrew Elkin

Domenic Tacca

Stramit

Matthew Kelm

Have questions? We're here to help.