Robotics for Education

Empower the next generation with cutting-edge automation tools in education. Our solutions provide hands-on learning experiences in robotics and technology, equipping students with practical skills for the future.

Explore how automation can enhance curriculum delivery and inspire innovation in the classroom.

Explore how automation can enhance curriculum delivery and inspire innovation in the classroom.

Provide hands-on experience that mirrors cutting-edge industries with factory-grade equipment and customizable portable robot modules.

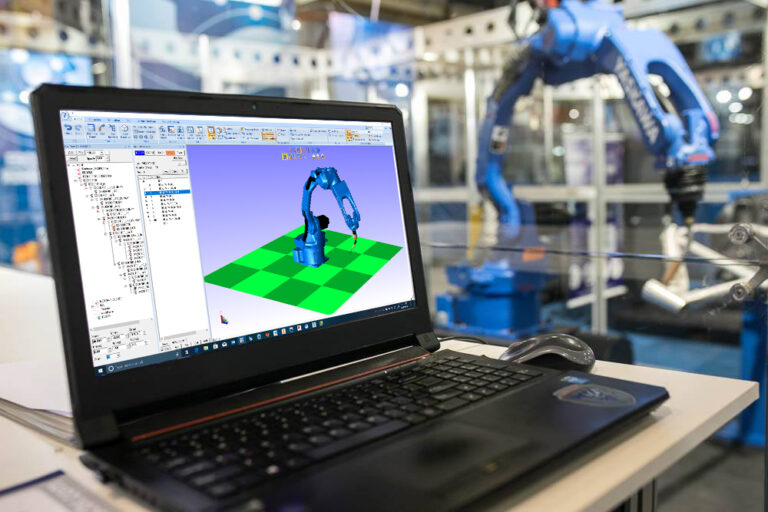

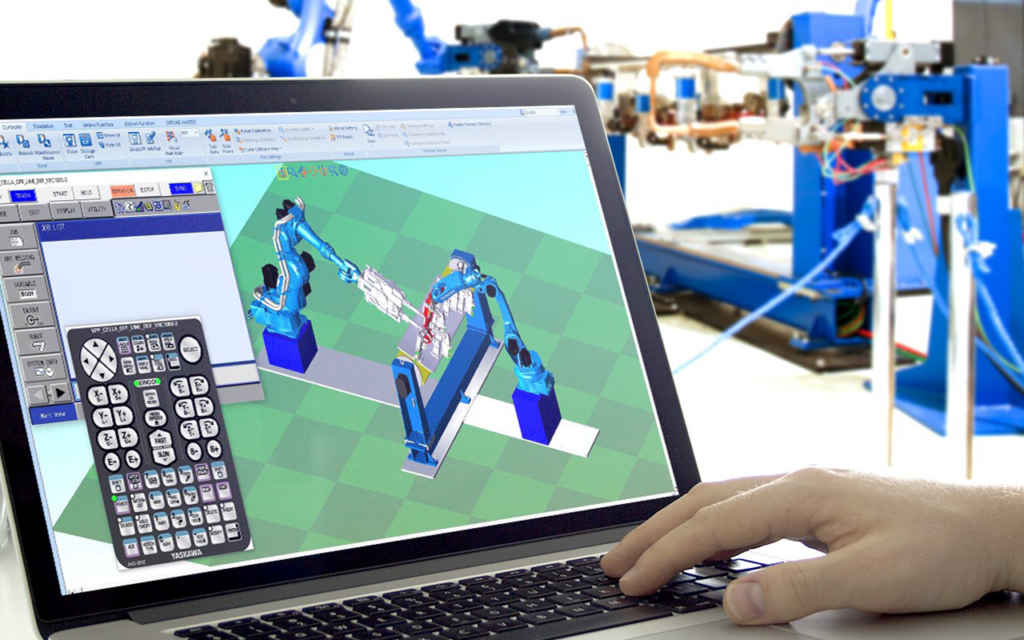

Simulate a full production environment safely with MotoSim® offline programming and immersive 3D workcell simulations.

MotoSim Touch provides a flexible, PC-based tool that lets students practice programming with a hardware pendant or virtual equivalent.

Simulate a full production environment safely with MotoSim® offline programming and immersive 3D workcell simulations.

MotoSim Touch provides a flexible, PC-based tool that lets students practice programming with a hardware pendant or virtual equivalent.

Educational Robots

YouTeachMe Robot Cell

This specially developed training cell is easy to operate and suitable for most offices and classrooms. The compact design includes a foldable table for transport through narrow doorways.

The cell includes a robot with gripper, controller, teach pendant and safety scanner, all installed on the station on casters. MotoSIM VRC Offline Simulation software is optional.

The cell includes a robot with gripper, controller, teach pendant and safety scanner, all installed on the station on casters. MotoSIM VRC Offline Simulation software is optional.

ArcWorld Micro

Complete with robot and controller the ArcWorld Micro with its hinged door opening has plenty to offer on a very small shape. With its built-in rotating positioner, it is ideal for the training of robot operators, demonstrations and other events.

Robotic Simulation Solutions

Experience seamless robotics training with MotoSim and MotoSim Touch. MotoSim offers powerful 3D simulation and offline programming, while MotoSim Touch adds hands-on interaction with a virtual pendant for immersive learning.

MotoSim Touch®

Master Yaskawa robot operation and programming with our PC-based simulator and physical pendant. Perfect for hands-on learning or on-demand training, it’s a flexible way to sharpen your robotics skills.

• Offline programming with virtual robot

• Portable PC-based education tool

• Offline programming with virtual robot

• Portable PC-based education tool

MotoSim® EG-VRC for Education™

Learn to operate and program Yaskawa robots in a virtual environment using our PC-based robot simulator. Designed for use in a networked, classroom environment, and perfect for on-demand refresher training.

• Offline programming with virtual robot

• Portable PC-based education tool

• Single network key allows for 20 workstation seats

• Offline programming with virtual robot

• Portable PC-based education tool

• Single network key allows for 20 workstation seats

Comprehensive support throughout the life of your equipment.

Robotic Automation™ Service Agreements are a cost-effective method of providing maintenance and technical support to keep your operations running. Our service agreement customers receive:

- Scheduled Annual Services

- 24 Hour Breakdown Service

- Discounts on Labour and Spares

- Customer Training and Support

- Telephone Support

- Planned Upgrade Management

- Customer Loyalty Benefits

- Consultancy Services

Case Study

Explore real-world success stories highlighting how Robotic Automation™ delivers innovative solutions and tangible results across industries.

Our Valued Customers

Testimonials

Read first hand accounts from clients who have experienced transformative results with our robotic automation solutions.

“One of the best executed projects I have been involved in whilst working for Downer”

Andrew Elkin

Head of Technology & Innovation Facilities & Asset Services, Downer Group

“I am extremely satisfied with the efficiency and reliability of our automated warehousing solution. The after sales service and technical support provided by the RA team has been exceptional.”

Domenic Tacca

Managing Director, Tacca Industries

‘After many months of careful consideration, looking at robotic solutions, we felt that Robotic Automation provided the best solution for increasing the efficiency and productivity of our steel manufacturing system. Their experienced team took time to review our manufacturing processes and identify opportunities to increase our production output, creating an automation solution which will provide flexibility for our business to grow and expand well into the future.’

Stramit

‘Robotic Automation provides service and support to our business which is second to none. Their experienced technicians have a detailed understand our business requirements and provide solutions which are adaptable to the ever-changing needs of our business’.

Matthew Kelm

Opal Group

Have questions? We're here to help.