Robotic Palletising – Double-Speed

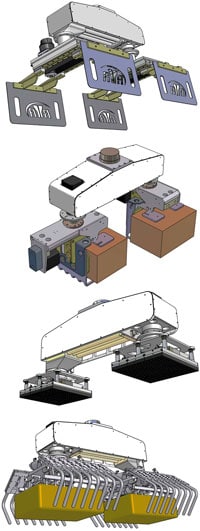

Using the 4-axis Servo Twin-Gripper designed by Robotic Automation P/L you can effectively add a “second pair of hands” to a robot.

Where production lines are fast-moving and there is rapid accumulation of finished product for palletising and despatch, this solution delivers a massive 100% increase in productivity while saving the floor-space, purchase, maintenance and running costs of a second palletiser and infeed lane.

This Australian-designed and patent-pending system (unique world-wide!) has no peer in the robotic marketplace, yet retains the flexibility of a robotic solution:

- Unlimited in its reprogrammable configurations to suit ever-changing products and packaging in today’s competitive markets

- Utilises standard-range MOTOMAN robotics:

– 40+ years of proven technology and development

– reliable and robust

– widely available parts and support

– retains maximum resale value - Australian designed and built:

– Built to Australian safety standards

– fast and local support

Application in Action : Paper Products

Gripping Alternatives to Suit Your Products :

In addition to handling a range of standard box-shaped products up to 750mm width, the 4 Axis Servo Gripper System has been adapted for use with Fork-tine, Pneumatic claw, and Vacuum grippers, allowing maximum flexibility in the types of products that can be handled and palletised:

- 4 Axis Servo-Vacuum Gripper System can handle varied shapes and non-porous packages such as cartons, jars, cans and tubes and also more delicate items such as shrink-wrapped trays of food. Uses suction to grip the top of the product only.

- 4 Axis Servo-Tine Gripper System handles heavier products that must be lifted and supported from beneath (where packaging may not support the product if gripped from top only).

- 4 Axis Servo-Pneumatic Claw Gripper System can handle the heavier products in the more irregular bags, porous sacks that must again be lifted and supported from beneath

Benefits Include :

- Reduced labor costs

- Reduced staff injuries from repetitive strain

- Reduced compensation claims

- Reduced lost production time

- Reduced damage to product and infrastructure

- Reduced staff turnover & management

- Increase productivity

- Increase product quality

- Increase product consistency

- Increase competitive advantage

- Increase safety