AMW 2024

March 18, 2024

Decades of robotic welding experience

Robotic Automation (RA) is looking forward to again being an integral part of Australian Manufacturing Week and will showcase the very latest in robotic manufacturing technology.

One of RA’s specialities is its welding division, which has long seen its MOTOMAN robotic welders utilised in numerous manufacturing applications.

A MOTOMAN Yaskawa Welding Cobot will be on display including live tutorials and demonstrations.

The Weld4Me Cobot package is an easy-to-use, Cobot-based MIG or MAG welding station. It offers high performance for small welding shops with small batch sizes and high variant diversity. The Cobot combines the strength and accuracy of the industrial robot with the safety features necessary for human-robot collaboration. The IP67 protection class provides superior capabilities for applications in rough welding environments.

Due to direct teaching and customised welding software, operating and programming the Weld4Me Cobot is easy to learn for welding personnel, even without prior robotics knowledge.

RA also offer self-contained Welding Cells for a flexible, space saving and cost-effective solution. Easy to install, operate and relocate, each ArcWorld cell is prepared for TIG, MIG or MAG welding, depending on requirements. The positioner variants of different types and sizes ensure high work piece flexibility and operator safety.

Check out RA’s Offline Programming Software to automatically generate robotic welding programs directly from CAD information. This easy-to-use desktop application makes offline robot programming simple and has powerful tools to ensure you get high-quality welding results with minimal programming effort.

The MotoSim® Simulation Software package similarly provides accurate 3D simulations of robot cells. This powerful simulation software can be used to optimise the whole system, reach modelling, and cycle time calculations. This enables highly accurate off-line programming of complex systems.

A working Laser Vision system will be on demonstration. The system enables the MOTOMAN robot to precisely find and track weld joints at high speeds and in real time, even while the parts are turning on a coordinated positioner resulting in precise optimised, highly accurate welds.

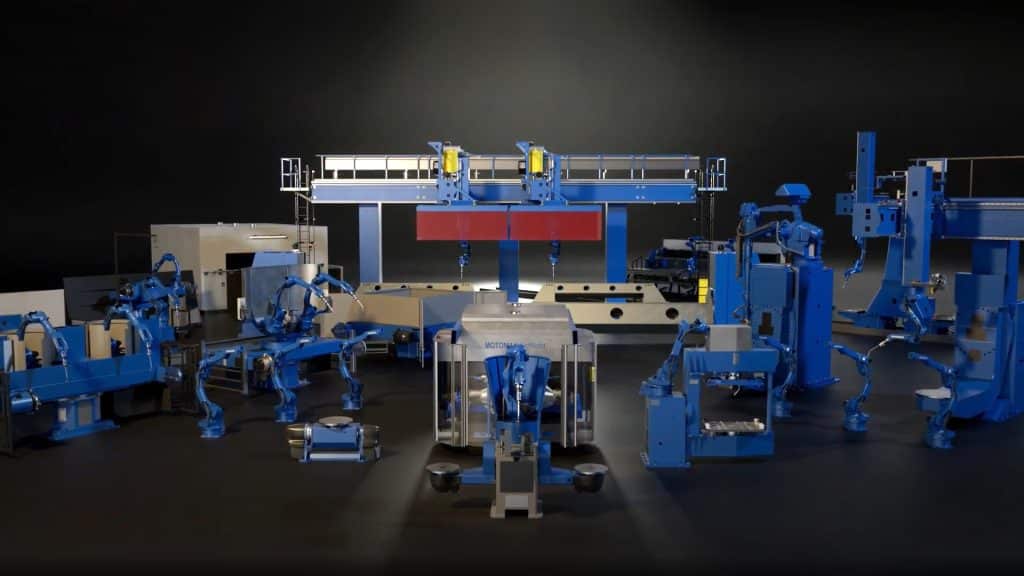

With so many years of robotic welding experience, Yaskawa provides the largest range of standard and customised work piece positioners with multiple simultaneously controlled axes, providing high speed and superb precision. This encompasses compatible Tracks and Gantries for all applications, setting RA apart as trusted advisors in system design without compromise.

While there will be many big blue robots on display, these large peripherals are far too big to exhibit at AMW. RA will have an many examples of functioning positioner units displayed on the big screen.

Be sure to come and see the RA team to see how we can provide the most suitable automated solution and return on investment to suit your manufacturing process.