Robotic Welding System saves time and defects!

March 6, 2020

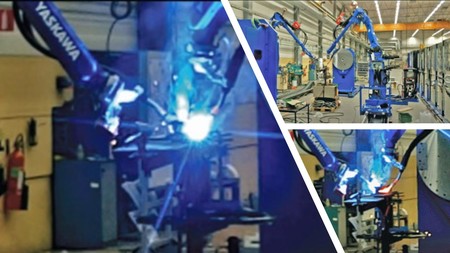

Robotic Welding System saves production time and defects! RA was selected by a leading Australian manufacturer to supply a large Robotic Welding System (pictured) for welding a variety of chassis several metres in length. RA’s solution improved consistency and quality during production cycles and reduced human error – saving production time and product defects!

RA’s solution featured two sleek designed MH50II-20 Motoman Robots with 20kg payload capacities and with a huge 3,106mm reach each. Also, fast and flexible with 7 degrees of freedom, as mounted on 24m servo tracks.

2 MH50II-20 Motoman long reach welding robots (pictured below) were fully integrated with a heavy duty welding equipment package comprising of a DM500 Tregaskiss air-cooled “Tough Gun” and collision sensor unit. Both robots operated in conjunction with 10 tonne capacity servo driven external axis head and, tail stock positioner mounted onto an independent servo external axis linear 14 metre track.

Solution Benefits:

• Increased staff safety

• Reduction in staff injuries & associated costs

• Increased productivity

• Reduced production time lost

• Increased product consistency & presentation

• Optimised floor-space & layout flexibility