Materials Handling

SOLUTION DESCRIPTION

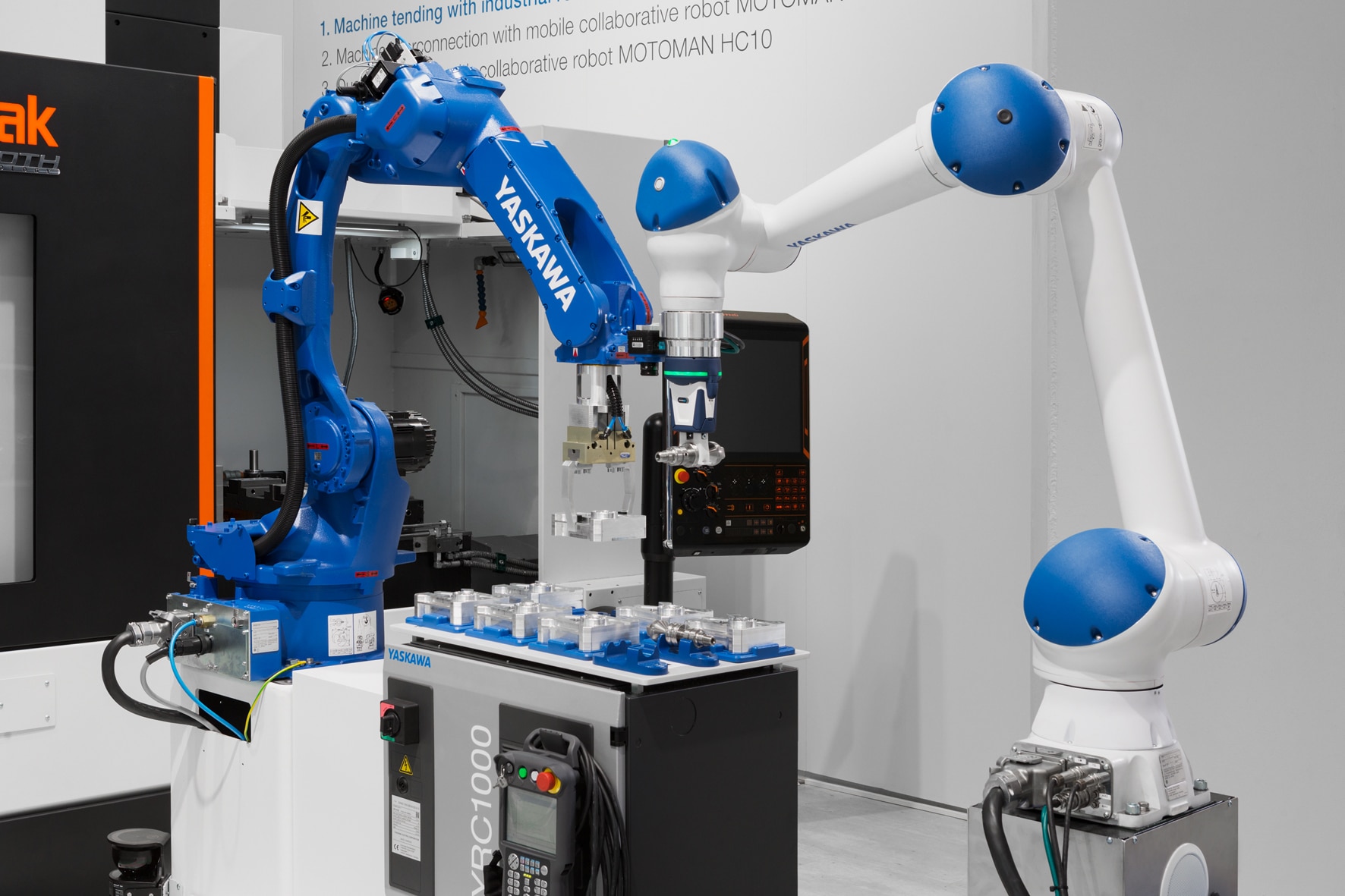

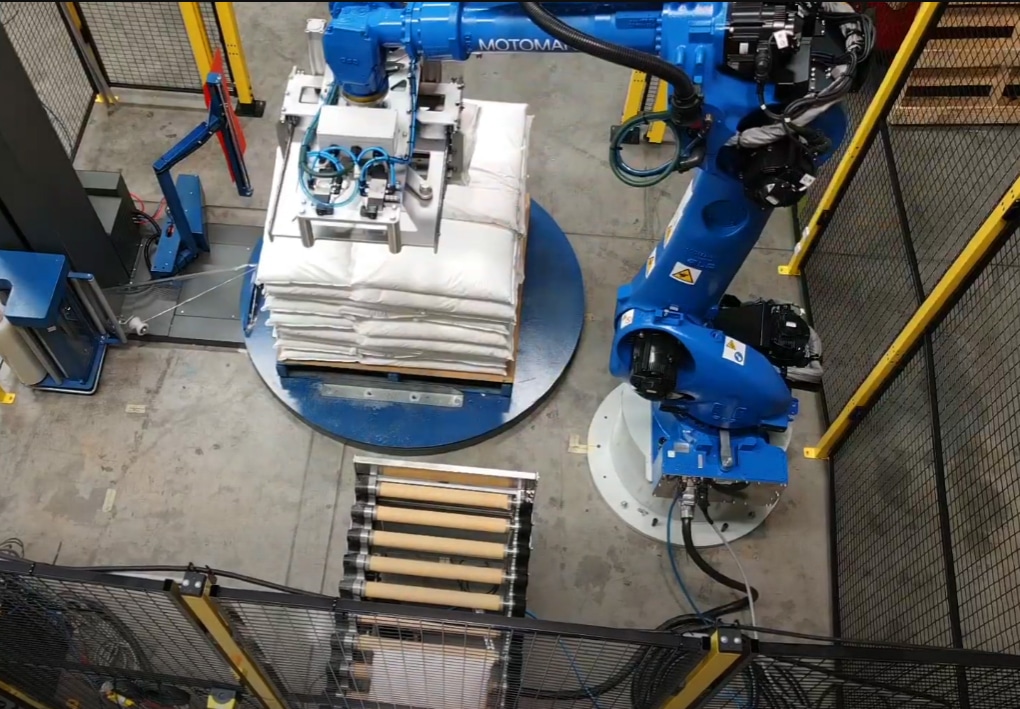

Virtually everything that a robot is designed to do involves automating materials handling applications with the term covering a full range of processes that involve the transfer or movement of materials, products, and parts in the warehouse, factory, logistics centre or healthcare facility. An umbrella term, material handling covers the full gamut of palletising, assembly, pick and pack, machine tending and other processes.

Robotic handling represents the opportunity to automate these repetitive tasks and is beneficial to any industry that has a need to move product or parts at scale, offering reductions in labour and changeover cost, and reduced floorspace; whilst providing increased speed, flexibility, and consistency, with repeat accuracy.

Robotic Automation can recommend a range of fast, flexible, and precise robotic handling solutions from our partner Yaskawa Motoman to best suit your materials handling application, layout and floorspace.

Robot selection is based on considerations of payload and reach, speed, and range of motion, as well as requirements for end of arm tooling and grippers.

Our 33 years’ experience and focus on delivering integrated solutions will ensure the best fit for your operation now, and into the future.

View some of our materials handling robots, including collaborative robots (cobots) through our Robot Selector.

End User Benefits

ENQUIRE NOW

GALLERY