Robotic Welding System Delivers Instant Benefits

Leading trailer and side tipper manufacturer has introduced the latest equipment and processes available into their manufacturing facility, that will see the company realise substantial efficiency improvements and cost savings in their already technologically advanced facility.

Customer Requirements

To improve quality and flow within the whole manufacturing environment.

In 2019, they began implementing a five-year plan that has a vision to improve its quality and flow within the whole manufacturing environment.

It was also necessary to add capacity because of the growth that the company was experiencing as well as to drive down production costs while at the same time getting clarity about its manufacturing performance.

System Implementation

Before the other new metal processing equipment were installed, a new factory had to be constructed to house the new equipment and to allow the company to move existing equipment into it to optimise the flow of processing material and the resultant processed components.

Smart Programming

Offline programming and 3D simulation software reduced manual work hours by 80% and programming time by 60%, from two weeks manual to four days offline.

Instant Benefits

Output has increased from 8 bins a day to between 16 and 20 bins a day – a 250% increase in production as well as cost reductions and quality improvements.

Equipment in Focus

Yaskawa Motoman has the largest available range of workpiece positioning peripherals.

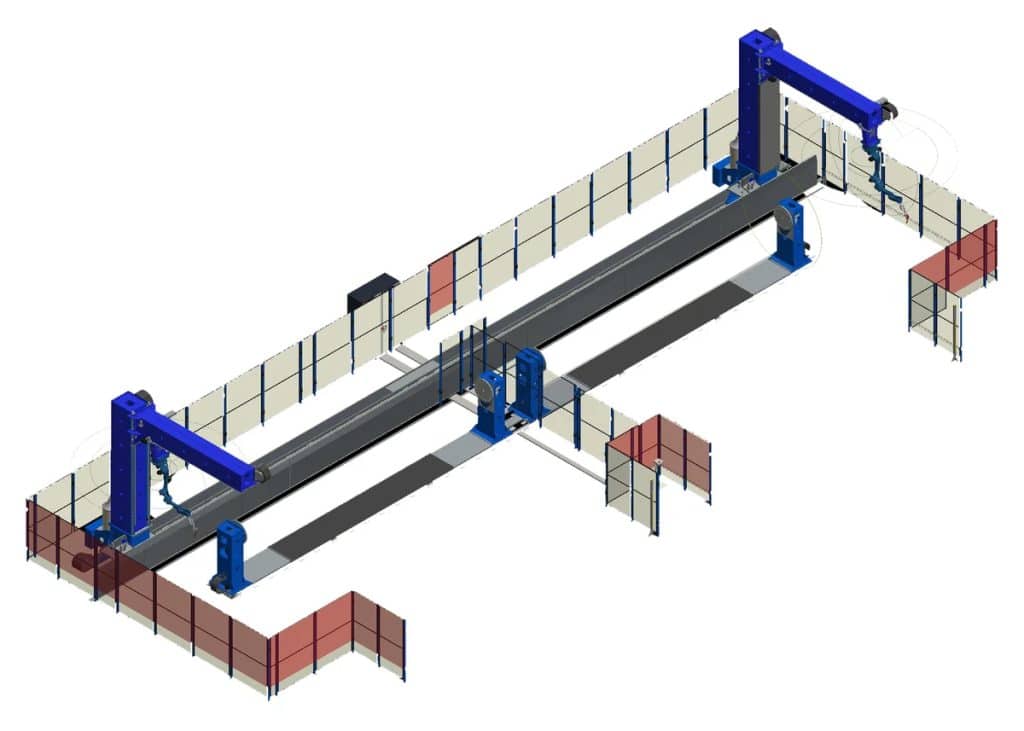

The 24-axis Yaskawa Motoman gallow gantry welding system is designed to produce very large components by providing fast, reliable and accurate welding solutions.

The two Yaskawa Motoman MH 2010 robots have a huge working area.

The Z and Y beam travel paths (horizontal and vertical servo axis) are up to 3m and 3.5m, the travel length of the entire system is 24 metres.

The support pillars are more than three metres high. The system is still referred to as a gantry even though the robots move along adjustable rails that are secured to the floor. As it is a modular robotic welding system it allows the robots to move along the bins and weld while the two end manipulators will rotate the bins as required.

The two Yaskawa Motoman robots have been fitted with cameras to monitor and track the seam welding in real time.