Robotic Pick and Place

SOLUTION DESCRIPTION

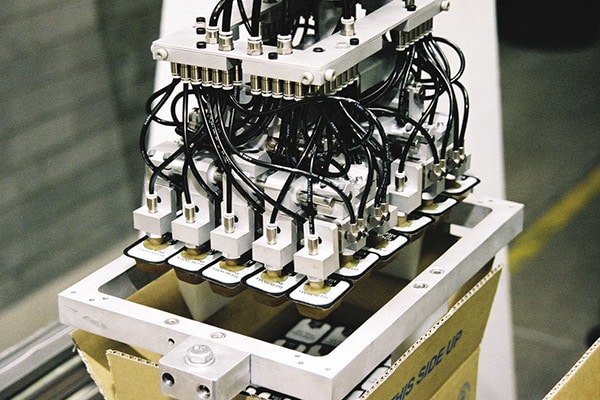

Robotic pick and place operations remove manual labour and introduce uninterrupted speed, reliability, inspection, sorting, accuracy and dexterity. Whether the aim is to pick and place primary or secondary products, robots can complete these tasks consistently at high speed without the need for breaks. Robotic Automation’s industrial pick and place robots are built with maximum repeatability.

To increase productivity and ease of implementation, Robotic Automation have developed dedicated solutions using Motoman Software that can coordinate multiple robots to pick and place large quantities of items per minute on a line. This kind of automation not only lowers cost, but improves productivity.

We represent Yaskawa Motoman picking and packing robot models supporting high-speed picking, collecting, transferring, sorting, packing and inspection.

Our robots are integrated within food and beverage, pharmaceutical, electronics and other consumer goods’ manufacturing.

Find out more about our robotic case packing capability and picking robot solutions delivered for a Retail Marketing Services company and Paper Towel and Tissue manufacturer.

End User Benefits

ENQUIRE NOW

GALLERY